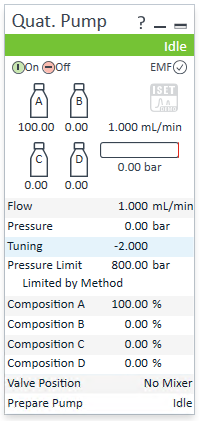

Tuning

For pumps operating as expected, the signal should stay in a range of –1 to +1 within the full scale of –2 to +2. Ideal performance is at 0.

Causes for changed behavior could be:

Gas bubbles in primary chamber

Suboptimal compressibility settings

Major leaks in seals or fittings

Problems with the valves

Blockage of filters or capillaries

NOTE

The tuning value does not change during the functions Prime or Conditioning.

Symptom | Possible Source | Possible Fix |

|---|---|---|

|

Tuning signal is negative (about –2 ), pressure signal is unstable. |

Air in primary pump chamber. |

Use a syringe to fill the solvent lines with solvent and use the prime function from your CDS. Afterwards load an appropriate method and condition the system. |

|

Tuning signal is negative (about –1.5 ), pressure signal is stable. |

Micro air bubbles in the primary pump chamber. |

Load an appropriate method and condition the system. |

|

Wrong solvent is set in the CDS or wrong solvent is connected. | Check solvents and solvent settings. | |

| Tuning signal is negative after Priming and Conditioning. | Back flow in inlet valve. |

Clean and check the valves, see maintenance section in the manual. Call Agilent service if the problem persists. |

|

Outlet valve not properly assembled. |

Clean and check the valves, see maintenance section in the manual. Call Agilent service if the problem persists. | |

|

Leaky piston seals and/or position-dependent leaks on the piston. |

Change seals in the pump head. Call Agilent service if the problem persists. | |

| Tuning signal is gradually decreasing over a time period. | Air is introduced into the primary pump chamber. |

Check performance of the degasser. |

|

Filters are starting to block. |

Change filters in the system. | |

|

Tuning signal is positive (about +1.5 ), pressure signal is stable. | Wrong solvent is set in the CDS or wrong solvent is connected. |

Check solvents and solvent settings. |

base-id: 4133412747

id: 4133412747