Wavelength Calibration

Wavelength Calibration of the detector is done using the zero-order position and 656 nm emission line position of the deuterium lamp. The calibration procedure involves two steps. First the grating is calibrated on the zero-order position. The stepper-motor step position where the zero-order maximum is detected is stored in the detector. Next, the grating is calibrated against the deuterium emission-line at 656 nm, and the motor position at which the maximum occurs is stored in the detector.

In addition to the zero-order and 656 nm (alpha-emission line) calibration, the beta-emission line at 486 nm and the three holmium lines are used for the complete wavelength calibration process. These holmium lines are at 360.8 nm, 418.5 nm and 536.4 nm.

NOTE

The wavelength verification/calibration takes about 2.5 min and is disabled within the first 10 min after ignition of the lamp because initial drift may distort the measurement.

When the lamp is turned ON, the 656 nm emission line position of the deuterium lamp is checked automatically.

The Wavelength Verification/Calibration is available in Agilent Lab Advisor (preferred tool).

When

The detector is calibrated at the factory, and under normal operating conditions should not require recalibration. However, it is advisable to recalibrate: |

|

NOTE

If the detector was repaired (opened covers), the wavelength calibration can be done 10 minutes after lamp on. A final wavelength calibration should be repeated after complete warm-up of the detector.

-

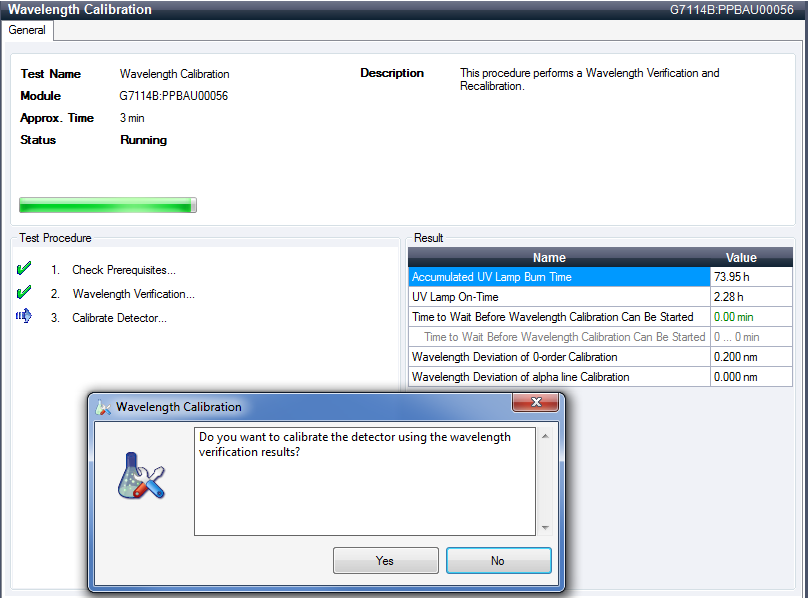

Run the Wavelength Calibration with the Agilent Lab Advisor (for further information see Online-Help of user interface).

Figure: Wavelength Calibration - Results If you select No, the test is aborted.

If you select Yes, the re-calibration is performed (the offset is corrected).

base-id: 3284440587

id: 3284440587