How to Achieve Lowest Carryover (G7167C, G7137B Hybrid Multisamplers)

Carryover is measured when residual peaks from a previous active-containing injection appear in a subsequent blank solvent injection. There will be carryover between active injections, which may lead to erroneous results. The level of carryover is reported as the area of the peak in the blank solution expressed as a percentage of the area in the previous active injection. The Hybrid Multisampler is optimized for lowest carryover by careful design of the flow path and use of materials in which sample adsorption is minimized. A carryover figure of 0.003 % should be achievable even when a triple quadrupole mass spectrometer is the detector. Operating settings of the sampler allow the user to set appropriate parameters to minimize carryover in any application involving compounds liable to stick in the system. The following functions can be used to minimize carryover:

Inner needle wash

Outer needle wash

Injection valve cleaning

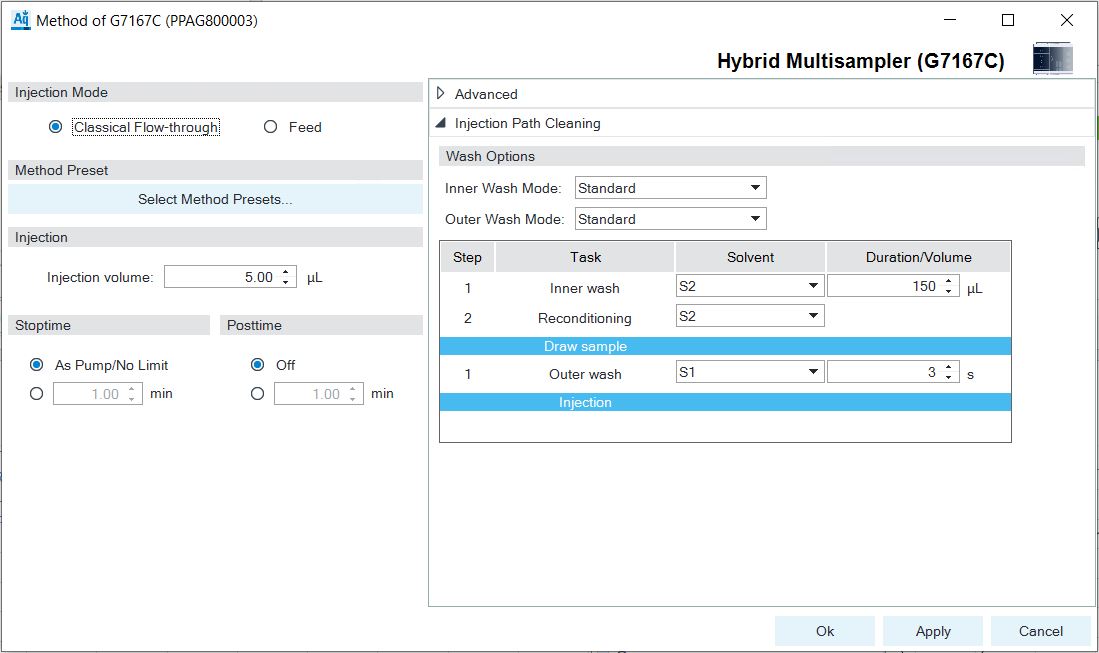

The flow path, including inside the needle, is continuously flushed in flow-through injection mode, providing good elimination of carryover for most situations. Between two injections, the volume or duration of the inner wash can be adjusted in the CDS. Automated delay volume reduction (ADVR) reduces both the delay volume and the flushing of the sampler and should not be used with analytes where carryover might be a problem.

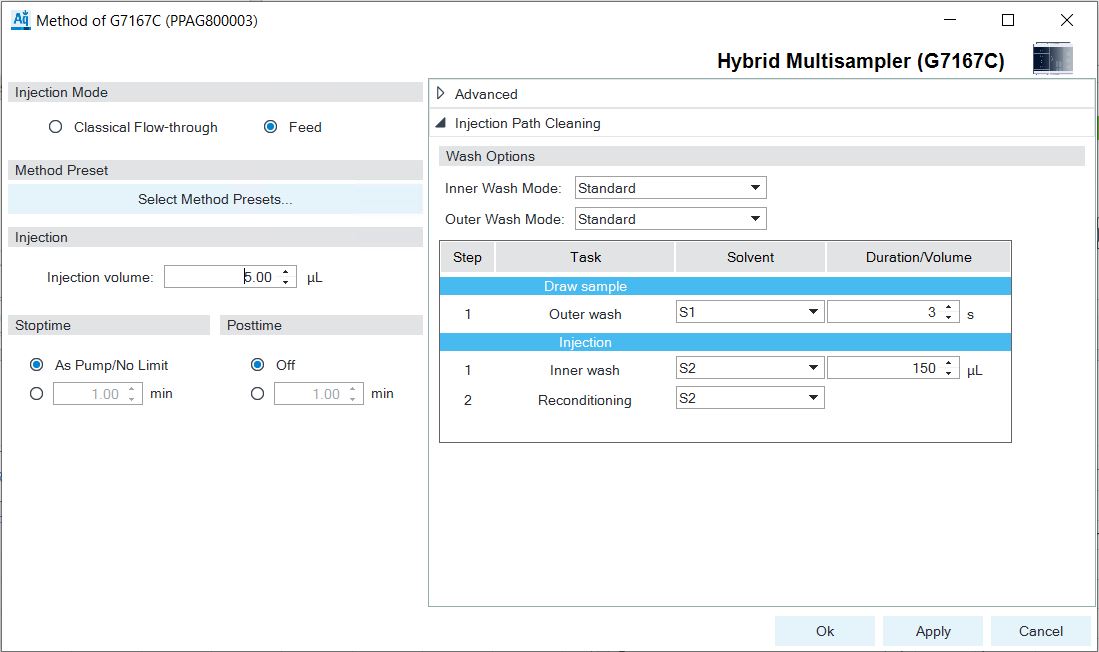

In Feed Injection, the flow path, including inside the needle, is flushed after each injection. The duration or volume can also be adjusted in the CDS. The definition of wash options is part of the Method Setup, as shown exemplarily in the following.

The outside of the needle can be washed using a wash vial in a specific location or the flush port. If a wash vial is chosen, then this vial should have no septum and should contain a solvent suitable for washing the sample from the needle. The septum is not used to avoid wiping contamination off the needle on the downstream only to re-apply it on the upstroke. The needle can be dipped into the vial multiple times. This action will be effective in removing a small degree of carryover, but for more effective external needle wash, use the needle wash port.

The needle wash port is located above and behind the needle seat, and the SSV/piezo pump delivers the wash solvent. It has a volume of 0.68 mL and the SSV/piezo pump delivers 5 mL/min, which means the flush port volume is completely refilled with fresh solvent in 7 s.

If the needle wash port is selected, the user can set how long the outside of the needle is to be washed with fresh solvent. This wash can last from 2 – 3 s in routine situations where carryover is less of a problem, to 10 – 20 s for complete washing.

The wash port and its solvent delivery pump and tubing should be regularly flushed to ensure the lowest carryover. For example, before using the system each day, prime the flush pump for three minutes with appropriate solvent.

When other measures have failed to eliminate carryover, it might be that analyte is adsorbing to the inner surfaces of the Injection Valve or External Sampling Valve. In this case, the auto clean feature in the CDS can be activated, and the valve will make additional switching movements to clean out the flow path. If the problem compounds need a high percentage of organic phase for elution, it is recommended to switch the valves at the high percentage of organic phase after the last peak has eluted. It is also recommended to switch the valves again after the initial conditions for the mobile phase have stabilized. This action ensures that the bypass groove in the rotor seal of the valves contains the gradient start conditions, which is especially important for flow rates below 0.5 mL/min. For samples where the outside of the needle cannot be cleaned sufficiently with water or alcohol from the flush pump, use wash vials with an appropriate solvent. With an injector program, several wash vials can be used for cleaning.

The optimum carryover performance of the sampler is achieved after a run-in period of new instruments or after the exchange of consumable parts (like needle, needle seat and valve parts). During injections in this period, surfaces of these parts adjust to each other. Regular preventive maintenance service is recommended as the carryover performance of the sampler depends on the integrity of these consumable parts.

If operated in Feed Injection mode, there are more parameters available to reach the goal of a low carryover.

Optimal adjustments are possible by:

Increasing the flush-out volume.

Decreasing the Feed speed.

Increasing the proportion of organic solvent in the flush-out solvent.

base-id: 6301335563

id: 27021604065558539